Custom refractory solutions transform industrial challenges into opportunities for enhanced performance. Tailored designs optimize thermal resistance and durability, adapting precisely to each facility’s needs. This approach not only improves efficiency but also extends equipment lifespan, ensuring reliability under extreme conditions. Partnering with specialists guarantees innovative materials and rigorous testing, delivering refractory products that excel in demanding environments every time.

Understanding Custom Refractory Solutions and Their Industry Applications

mxs-refractories.com specializes in developing tailored heat-resistant linings designed for various high-temperature industries. Custom refractory solutions involve engineering materials and shapes precisely suited to specific operational environments, ensuring maximal efficiency and longevity.

Topic to read : Unlocking Market Potential: Data-Driven Strategies for Swansea Travel Agencies in Effective Customer Segmentation

Industries like steel, glass, petrochemical, and power generation benefit significantly from these bespoke solutions. Each sector faces unique challenges, such as chemical exposure, thermal shock, and mechanical stresses. Customized refractories address these challenges by offering optimized thermal performance and durability, reducing downtime and maintenance costs.

Factors influencing material choice include operating temperature, chemical composition, and structural design. For example, fireproof lining systems and refractory brick fabrication are tailored to withstand extreme conditions.

Also read : Master relocation stress management for a successful move

Research indicates that companies like mxs-refractories.com prioritize precise engineering, material quality, and client collaboration for effective solutions. You can view more details on this page: mxs-refractories.com.

Custom Refractory Engineering and Product Development Processes

Consultation and Design Specification

Precision begins with refractory materials customization, as engineers gather detailed operational data—such as system temperature, chemical exposure, and mechanical stresses. Collaborative sessions clarify project scope, allowing industry experts to identify the best custom refractory solutions or recommend tailored heat-resistant linings for complex industrial refractory applications. Using refractory design software tools, specifications are refined to optimize refractory system design, which is essential for achieving performance objectives across applications like power plant refractory systems and metal smelting refractory needs.

Prototype Testing and Validation

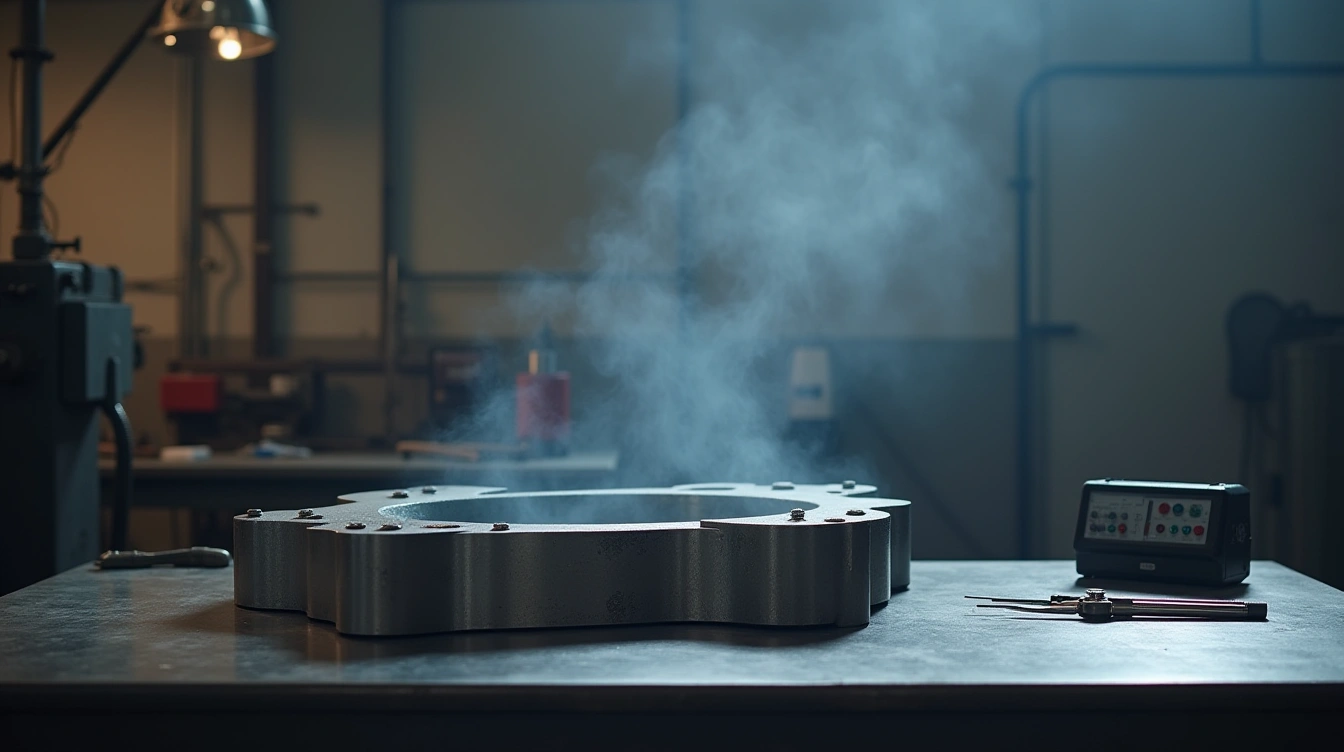

Prototype development embodies personalized refractory engineering; custom refractory shapes are fabricated based on shared engineering drawings. Customers can evaluate products in real operational settings, focusing on refractory performance testing and thermal insulation solutions during stress trials. Any deviations from expected results feed into refractory design optimization—adjusting material composition or fireproof lining systems. This iterative process safeguards structural integrity and maximizes refractory wear resistance.

Production and Quality Assurance

Manufacturing launches after validation, emphasizing strict refractory quality assurance protocols. Adherence to refractory industry standards guarantees that refractory brick fabrication and ceramic fiber products meet demanding requirements. Through robust refractory installation services and scheduled post-production testing, clients receive reliable, cost-effective customized kiln linings and industrial furnace linings—optimized for durability, thermal shock resistance, and best-in-class heat containment technology.

Industry-Specific Applications and Benefits of Custom Refractory Solutions

Steel and Metal Industry

Custom refractory solutions play a transformative role in the steel and metal sectors. Modern industrial refractory applications demand steel mill refractory solutions that stand up to extreme heat and mechanical stress during metal smelting operations. Refractory materials customization addresses the need for enhanced wear resistance and thermal shock resistance, ensuring furnace linings, ladles, and continuous casting equipment maintain structural integrity. Custom refractory craftsmanship involves engineering highly tailored heat-resistant linings matched to aggressive chemical and temperature fluctuations, maximizing operational reliability.

Petrochemical and Chemical Processing

Within petrochemical refractory applications, reactors and vessels must endure intense chemical exposure and rapid thermal cycling. Personalized refractory engineering integrates material science with high-performance thermal insulation solutions to extend refractory lining lifespan. Refractory design optimization incorporates testing and iterative improvements to withstand dynamic processing environments. Achieving optimal industrial furnace linings for this sector requires rigorous refractory repair and maintenance protocols, reducing downtime and operational risks substantially.

Glass and Cement Industries

For glass and cement operations, customized kiln linings and refractory brick fabrication are essential to energy management and durability. Integration of ceramic fiber products aids in efficient insulation, controlling heat flow, and reducing fuel consumption. By applying custom refractory shapes in melting tanks and kilns, companies benefit from improved heat containment technology and prolonged refractory material durability—key for integrated efficient, safe, and sustainable production.

Custom Refractory Solutions: Design, Materials, and Testing

Custom refractory solutions begin with a precise assessment of industry needs. Initial consultation is essential—clients share process details like expected temperatures, chemical exposure, mechanical loads, and intended geometries. This information guides refractory materials customization and the selection of appropriate base recipes or engineered blends.

Drawing on these specifications, specialists develop custom refractory shapes for furnace or kiln interiors. Technical teams use tailored heat-resistant linings, industrial furnace linings, or fireproof lining systems to match complex operational requirements. Whether it’s for steel mill refractory solutions, power plant refractory systems, or petrochemical refractory applications, each solution is designed for optimum efficiency.

Prototype development follows. Clients submit precise drawings, facilitating refractory brick fabrication or custom castable refractory solutions. Performance is validated through refractory performance testing and thermal cycling in actual working environments, ensuring alignment with performance, durability, and thermal shock resistance goals.

Quality checks occur at every step. Refractory installation services adhere to established refractory industry standards. Post-approval, full-scale production leverages refractory quality assurance—supporting safety, fit, and refractory structural integrity. Professional aftercare promotes trouble-free, long-life operation for all custom refractory craftsmanship.